측정방식:

- Diode Laser를 이용한 IR 대역의 in-situ방식

- TDLAS(Tuneable Diode Laser Absorption Spectroscopy)

- NOx, NH3, O2 탈질 설비 제어

- HCI, H₂S 소각로 / 매립지

- O2 정유사 "SAR" 프로세스의 제어

- H₂O CEMS용 모니터링

- O2 폭발 위험 프로세스의 폭발 하한치 제어

- CO, CO₂, O2 정유사 RFCC 프로세스의 모니터링

- CO, O2 보일러, 연소제어, 정유 공장의 히터, 제철공장의 퍼네스 등의 연소제어

- Dust: Scattered/Transmission mode로 근거리(0.5~3m)에서 원거리(~10m)까지 측정

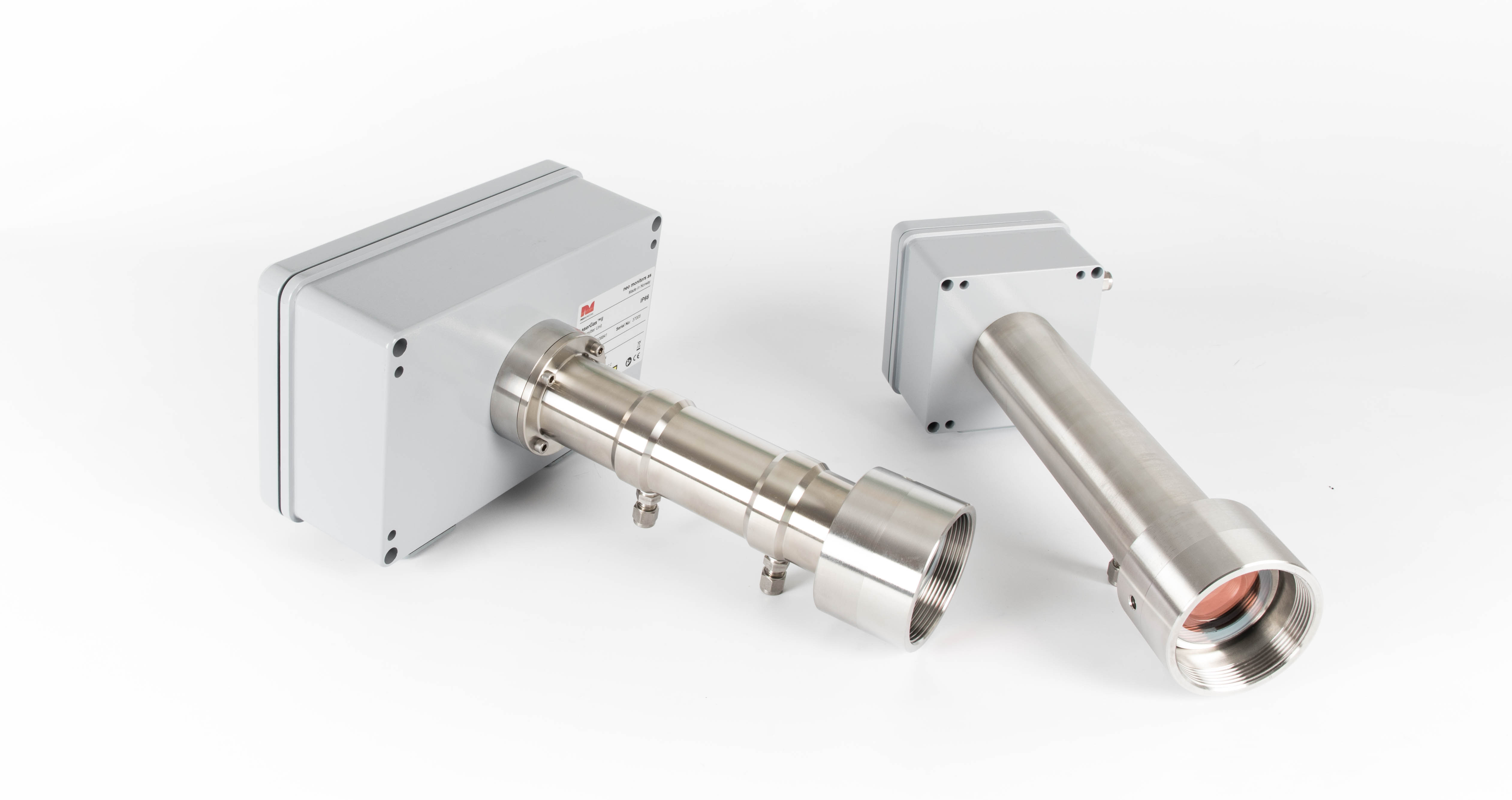

NEO Monitors의 LaserGas™ II SP H2는 TDLAS(Tunable Diode Laser Absorption Spectroscopy) 즉, 레이저를 이용한 '비접촉식 광학측정 방식'을 사용합니다. 측정 센서는 오염 또는 부식성 물질로부터 영향을 받지 않으며, 정기적인 유지보수가 필요하지 않습니다. 샘플링 장치가 필요없는 Laser TDLAS 방식을 사용함으로써 측정 값은 더 정확해지고, 샘플링과 관련된 오류가 감소하게 됩니다. LaserGas™ II SP H2 분석기는 플랜지에 직접 장착되어 실시간 측정이 이루어지며, 퍼지 가스 연결과 얼라이먼트를 쉽게 해주는 'Tiling Mechanism'이 적용됩니다.

주요 특징

• 빠른 응답 시간

• 가스 샘플링 장치가 필요 없음; 비접촉식 광학 측정

• In-situ 측정 방식

• 측정 시 타 가스 간섭 없음

• 다양한 프로세스 조건에 적합

- 고온/저온

- 고농도 분진

- 부식성 가스 등

• 스택 내부 전체 구간에 대한 농도 측정

• 스팬 체크 옵션의 일체화

• Zero drift 없음

• 안정적인 교정(Calibration)

• 지속적인 내부 상태 점검

적용 사례

• 화학 산업

• 석유 화학 산업

• 금속 산업

• 천연가스 프로세싱

• 염소(Chlorine) 생산

• 안전 애플리케이션

• PVC 생산

• 프로세스 제어

• 유리 생산

주요 장점

• In-situ 모니터링

• 믿을 수 있는 실시간(Real-time) 분석기

• 낮은 유지보수 비용

• 대기 배출의 감소

• 일일 운용 비용의 절감

• 간단한 설치 및 손쉬운 사용법

• 프로세스의 최적화

• 증명된 측정 기술

• Specifications

- Optical Path Length: Typically 0.5 - 5 m

- Accuracy: Application dependent

- Repeatability: 2% of range (gas & application dependent)

• Environmental conditions

- * Certified Operating temperatures: -20 °C - +55 °C

- Storage temperature: -20 °C to +55 °C

- Protection classification: IP66

• Inputs / outputs

- Analog output(3): 4 - 20 mA current loop (concentration, transmission)

- Digital output: TCP/IP, MODBUS, Optional fibre optic

- Relay output (3): High gas, Maintenance warning and fault

- Analog input (2): 4 - 20 mA Process temperature and pressure reading

• Ratings

- Input transmitter unit: 18 - 32 VDC, max. 20W

- 4 - 20 mA output: 500 Ohm max. isolated

- Relay output: 1 A at 30 V DC/AC

• Safety

- Laser class: Class 1 according to IEC 60825-1

- CE: Certified

- EMC: Conformant with directive 2014/30/EU

• Approvals

- IECEx/ATEX zone 1: II 2 G Ex pxb [op is Ga] IIC T4 Gb, II 2 D Ex pxb [op is Da] IIIC T100°C Db

- IECEx/ATEX zone 2: II 3 G Ex nA nC [op is Ga] IIC T4 Gc, II 3 D Ex tc [op is Da] IIIC T100°C Dc

- CSA: Class 1, Div.2, Groups A, B, C and D; Temperature Code T4

• Installation and Operation

- Flange dimension: DN 50/PN10 or ANSI 2"/150lbs(other dimensions on request)

- Alignment tolerances: Flanges parallel within 1.5°

- Purge flow: Dry and oil-free pressurised air or nitrogen 10 -50 l/min(application dependent)

- Purge air quality: ISO 8573-1:2010, class 3 or better

• Maintenance

- Visual inspection: Recommended every 6 - 12 months

- Calibration: Check recommended every 12 months

- Validation: Build-in cell for span check with H2 gas (non ATEX/IECEx/CSA) or integrated span check (all versions)

• Dimensions / Weight

- Transmitter unit: 405mm (plus 65 for purge unit) x 270mm x 170mm, 6.2kg

- Transmitter unit (Ex ver.): 405mm (plus 65 for purge unit) x 270mm x 310mm, 7.9kg

- Receiver unit: 355mm (plus 65 for purge unit) x 125mm x 125mm, 3.9kg

* Certified ambient temperature range: -20°C to +55°C

Extended ambient temperature ranges: -30°C to +55°C or -20°C to +65°C (non-certified) available upon request, subject to application.

| Gas | Detection limit | Min range | Max range | Response time | Temp | Pressure |

|---|---|---|---|---|---|---|

| H2 | 0.1 %Vol | 0-5 %Vol | 0-100 %Vol | 2sec | -50°C ~ 250°C | 0.5BarA ~ 10BarA |

NOTE: Detection limits are specified as the 95% confidence interval for 1m optical path and gas temperature/ pressure = 25°C / 1 BarA. Measured in N2.