측정방식:

- Diode Laser를 이용한 IR 대역의 in-situ방식

- TDLAS(Tuneable Diode Laser Absorption Spectroscopy)

- NOx, NH3, O2 탈질 설비 제어

- HCI, H₂S 소각로 / 매립지

- O2 정유사 "SAR" 프로세스의 제어

- H₂O CEMS용 모니터링

- O2 폭발 위험 프로세스의 폭발 하한치 제어

- CO, CO₂, O2 정유사 RFCC 프로세스의 모니터링

- CO, O2 보일러, 연소제어, 정유 공장의 히터, 제철공장의 퍼네스 등의 연소제어

- Dust: Scattered/Transmission mode로 근거리(0.5~3m)에서 원거리(~10m)까지 측정

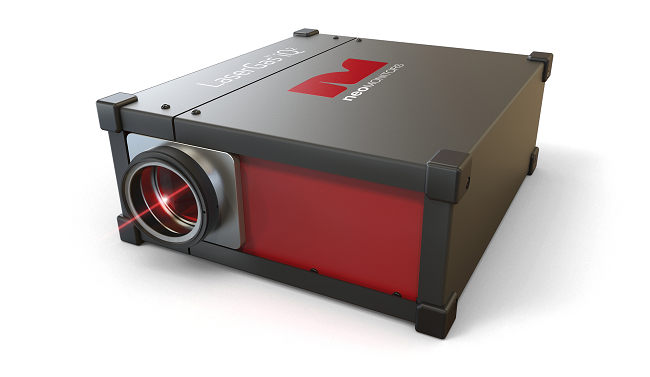

NEO Monitors의 LaserGas™ iQ² ‘GAME-CHANGER’ 는 종래 Laser Gas 분석기의 단점이었던 ‘1 Gas 1 분석기’의 한계를 극복하여, 연소 분석 시 여러 대의 분석기를 설치할 필요 없이 하나의 분석기로 네 가지의 가스(O2, CO, CH4, H2O) 및 온도를 측정할 수 있는 최초의 TDLAS 분석기입니다. 최첨단 설계와 획기적인 기능으로 뛰어난 신뢰성과 내구성을 제공합니다. 단일 플랜지 솔루션을 옵션으로 제공함으로써 설치 비용을 크게 절감할 수 있습니다. 사용자는 기존 분석기의 폭발 위험이나 고비용 유지 보수 문제를 iQ2 분석기로 해결할 수 있습니다.

주요 특징

• 측정 시 타 가스 간섭 없음

• 공장 출하 시 교정(Calibration) 완료

• Zero Drift 없음

• Transceiver(일체형 송수신부) 구성

• 다양한 구성

- Cross Stack

- One-Flange with Probe

- Open Path

• 자동 게인 컨트롤

• In-situ 실시간 측정

• Span check 일체화(Application dependent)

• 필요에 따라 여러 가스 조합 가능

(O2 + ppm CO / O2 + ppm CO + CH4 / O2 + ppm CO + CH4 + H2O, plus 온도)

적용 사례

• 연소 분석

• FCC Unit(유동 접촉 분해)

• Package Boiler

• Process heaters

• Electrostatic precipitators

• VCM waste gas recovery

• Reformer Gas

• 소각로

주요 장점

• 최대 4개의 가스(O2, CO, CH4, H2O) 및 온도 측정 가능

• 1300 ℃ 고온 연소 공정에서 적용

• 설치 비용 절감

• 낮은 유지보수 비용

• 간단한 설치 및 손쉬운 사용법

• 이중 경로 길이로 저 농도의 흡수 신호 증가

• 극한 고온 환경에서도 스택의 가장 차가운 측면에 트랜시버 설치 가능

• 검증된 기술

• 새로운 가스 및/또는 기타 가스의 조합을 측정할 수 있는 유연성을 갖춘 설계

• SPECIFICATIONS

- Max. process gas temperature: 1300 °C

- Max. process gas pressure: 1.5 barA

- Optical path length: max 20m

- Response time: 5 seconds

• ENVIRONMENTAL CONDITIONS

- Operating temperatures: -40 °C - +55 °C

- Storage temperatures: -40 °C to +70 °C

- Protection classification: IP66

• INPUT / OUTPUT

- Analog output: 4 - 20 mA current loop

- Digital output: Ethernet (TCP/IP)

- Relay output (4): High gas, warning and fault (normally closed)

- Analog input (2): 4 - 20 mA Process temperature and pressure reading

• RATINGS

- Power supply: 24 VDC (18 - 30 VDC)

- Power consumptions: max 30W

- 4 - 20 mA: 500 Ohm max isolated

- Relay output: 1 A at 30 V DC

• SAFETY

- Laser class: Class 1M according to IEC 60825-1, eye safe

- CE: Certified

- EMC: Conformant with directive 2014/30/EU

• APPROVALS

- IECEx/ATEX zone 1: II 2 G Ex pxb IIC T5 Gb, II 2 D Ex pxb IIIC T100 °C Db

- CSA: Class I, Div.2, Groups A, B, C and D; Temp. Code T5

- ATEX rating connetion box: II 2 GD Ex e IIC T5 Gb -40 °C ≤ Ta ≤ 65 °C NEMA 4x

• INSTALLATION AND OPERATION

- Flange dimension:

DN 80/PN 10-40 (Center Ø3") or ANSI 3" #150(#300)(Center Ø3"), ANSI 4" #300

- Instrument purge: Application dependent

Nitrogen

- Probe purge (Optional): Nitrogen

• MAINTENANCE

- Calibration: Check recommended every 12 months

- Validation: In-situ span check with optional internal cell(application dependent)

• DIMENSIONS / WEIGHT

- Transceiver: 461mm x 399mm x 174mm, 15 kg

♦ LaserGas™ iQ² X-stack O2 + CO ppm Standard (below 500 °C)

| Min | Max | LDL/precision | |

|---|---|---|---|

| CO Range | 1-100 ppm | 0-10000 ppm | 1 ppm |

| O2(N2 purge) | 0-2% | 0-25% | 0.02% |

| Process path length | 0.5m | 20m | |

| Process temperature | -40 ℃ | 500 ℃ | |

| Process pressure | 0.7 BarA | 1.5 BarA | |

| CH4 add-on | 0-1%* meter | 0-5%* meter | 0.01% |

| Temperature add-on(N2 purge) | -40 ℃ | 500 ℃ | 15 ℃ |

♦ LaserGas™ iQ² X-stack O2 + CO ppm High temperature (above 500 °C)

| Min | Max | LDL/precision | |

|---|---|---|---|

| CO Range | 1-200 ppm | 0-20000 ppm | 3 ppm |

| O2(N2 purge) | 0-5% | 0-25% | 0.05% |

| O2(Air purge) | - | 0-25% | 0.2% |

| Process path length | 0.5m | 20m | |

| Process temperature | 500 ℃ | 1300 ℃ | |

| Process pressure | 0.7 BarA | 1.5 BarA | |

| CH4 add-on | 0-5%* meter | 0-10%* meter | 0.05% |

| H2O add-on | - | 0-40% | 2% |

| Temperature add-on | 500 ℃ | 1300 ℃ | 30 ℃ |

| Temperature add-on(N2 purge) | -40 ℃ | 1300 ℃ | 20 ℃ |